The RF amplifier module is one of the core components in anti-drone systems. These RF modules directly impact the effectiveness of interference against drones. But how are they made? How do they ensure continuous and stable operation?

Here, we’ve prepared a detailed flowchart for bulk RF module ordering from a factory. Let’s dive into the process:

Communication Phase

Specifications Confirmation

At this stage, the primary task of our sales team is to confirm your specific RF module requirements. There are 3 key aspects to consider:

Power: Common options include 30W, 50W, 100W, 150W, 200W, and others. Based on our experience, 50W and 100W are the most popular and cost-effective choices, considering factors such as interference effectiveness, heat generation, operational stability, size, weight, and production costs.

Frequency: Frequency can be a confusing concept. Zorelock’s RF modules can cover frequencies ranging from 20MHz to 6GHz. However, this does not mean a gain bandwidth of nearly 6000MHz! It refers to bandwidths, such as 700-800MHz or 5150-5350MHz, within a 200MHz range, with a starting frequency of ≥20MHz and a cutoff frequency of ≤6GHz.

Functionality: Our sales team will ask whether you need an enable switch, a Software Defined Radio (SDR)-based digital signal module, or a monitoring feature that tracks RF module status via high/low-level changes on an XH2.54 connector. These requirements define the module’s additional features, expanding its application and meeting your product development needs.

Once these specifications are confirmed, our team will select the most suitable RF module model from our catalog and review key components and PCB designs with you. Atthis stage, we may produce samples for your approval and discuss pricing and customization options for the bulk order.

Raw Material Confirmation

After confirming your order specifications and quantities, we use our inventory management system to check stock levels of required raw materials and estimate the procurement and delivery times.

Production Cycle Confirmation

We will estimate the production cycle based on the current workshop order queue and your anticipated payment date, ensuring a clear delivery timeline.

Advance Payment Confirmation

Once you make the advance payment, production officially begins.

Production Preparation Phase

Order Information Transmitted to Engineers and PMC

All important order details, including specific test requirements (e.g., RBW/VBW values or VCO signal scanning rates), will be communicated to our engineers. This ensures that the order is processed efficiently and delivered on time.

Raw Material Procurement Plan

At this stage, we procure more raw materials than initially needed. Although this may increase our inventory costs, it ensures smooth production by compensating for material loss during the manufacturing process.

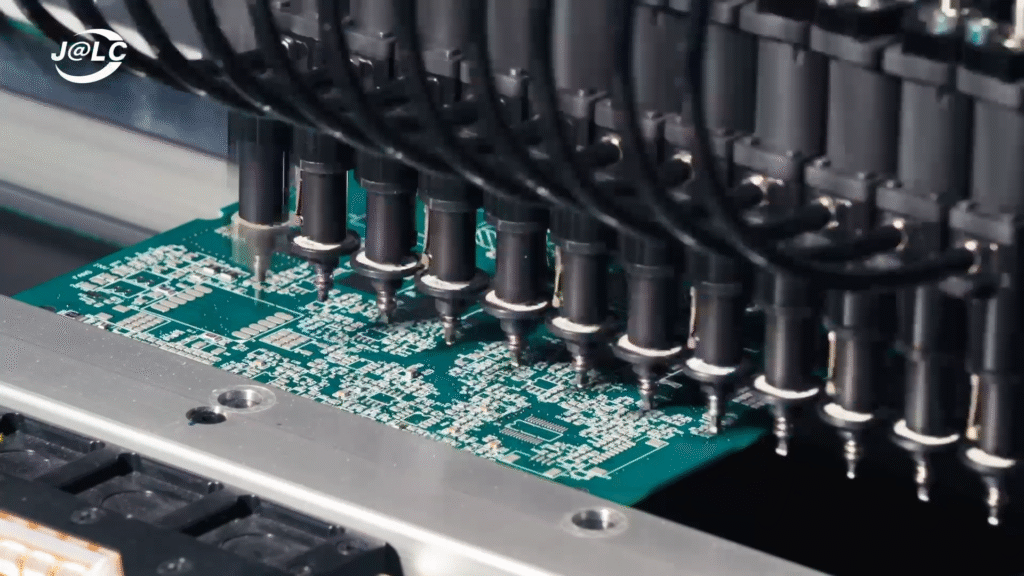

Automated SMT

For most orders, except a few sample ones, the entire PCB surface-mount process is automated, significantly improving production efficiency and reducing the possibility of soldering defects like cold or missing solder joints.

Material Transfer to Workshop and Assembly Start

Once materials are prepared, they are sent to the workshop to begin the assembly process.

Production Phase

Assembly

This involves the assembly and soldering of key components, such as LDMOS or GaN transistors and circulators. These larger components require manual assembly, including the use of screws to secure them, as they cannot be placed by automated SMT machines.

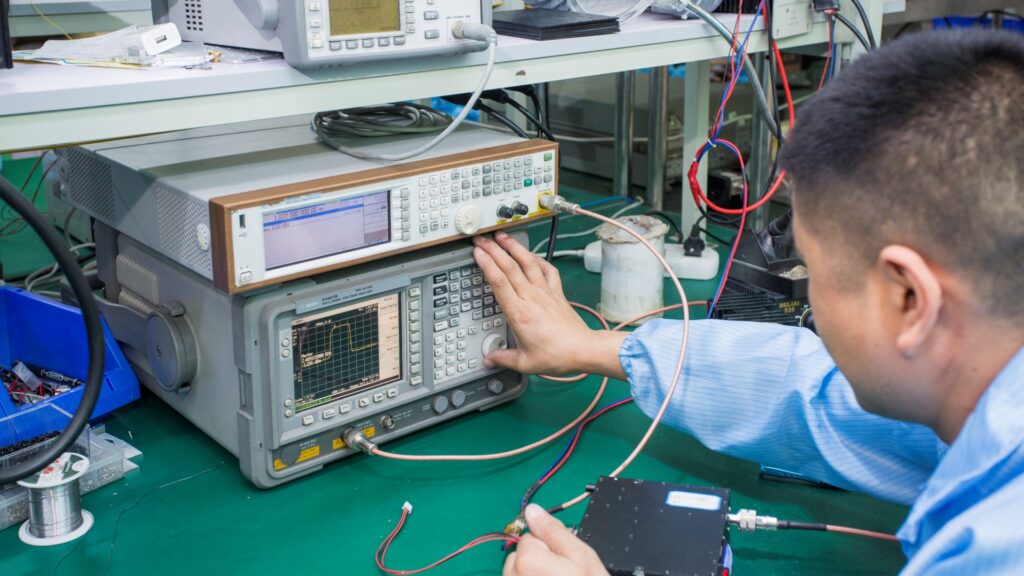

Spectral Performance Testing

Once the modules are assembled, our engineers test them using spectrum analyzers and power meters. The key performance indicators include:

· Checking for significant spurious emissions.

· Ensuring no self-excited oscillations occur.

· Verifying that the module’s frequency range matches customer requirements.

· Checking in-band power fluctuation.

· Measuring in-band average power, as determined by the power meter, not just the power displayed on the spectrum analyzer.

· Check the spectrum performance of the module under different ambient temperatures.

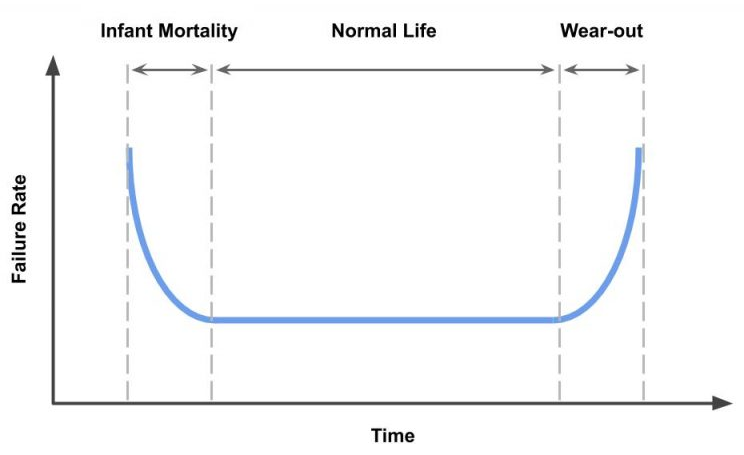

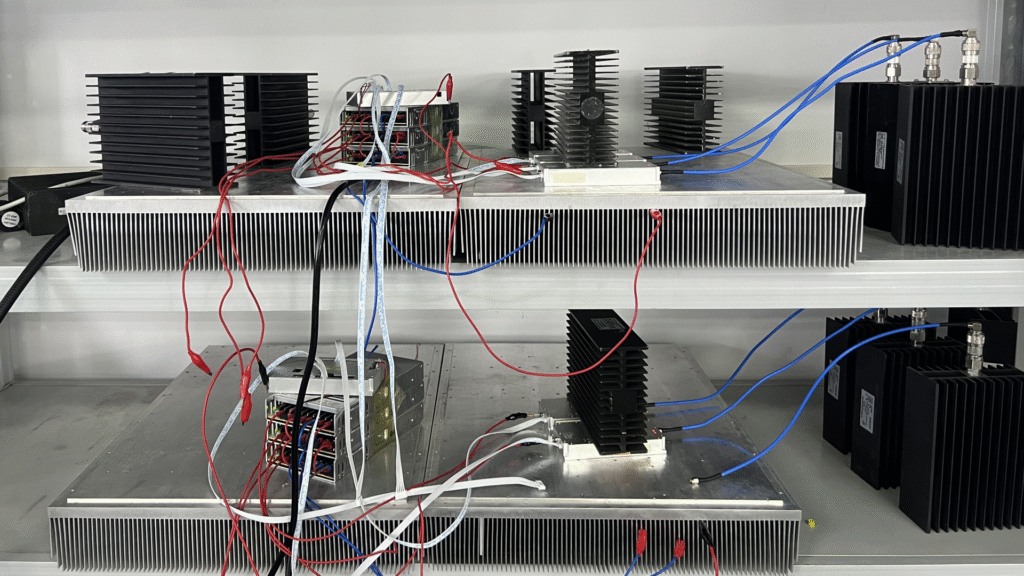

Burn-In Testing

Burn-in testing helps identify potential hardware failures, eliminating most early-stage issues. This process follows the “bathtub curve,” where any modules that fail are returned for inspection or discarded.

Quality Control Inspection

After burn-in testing, our QC team inspects the modules for external defects, component security, and connector durability. The RF performance is also recorded to ensure the modules meet the required standards before proceeding to packaging.

Packing Phase

Labeling

Each module is labeled with a unique SN code and production date for traceability.

Packing

We use EPE pearl cotton and 5-layer corrugated paper to pack the modules securely, ensuring they are ready for safe international shipping.

Final Payment Received

Once you have completed the final payment, we will be ready to arrange the shipment.

Delivery

Modules are shipped either in batches or as a full order, depending on your needs.

About After-sales

Our after-sales guarantee period is one year from the date of delivery. If the module is damaged due to non-human factors during installation or use, you can communicate directly with your salesperson and we will make and resend you the modules of the same quantity and specifications.

Conclusion: Complete process for purchasing RF amplifier module from the manufacturer

The process from communication to production and delivery involves numerous steps, each carefully planned to ensure a smooth experience for our clients. If you have any further questions or need more information about our ordering and production process, don’t hesitate to contact our sales team for expert technical support directly from the manufacturer!